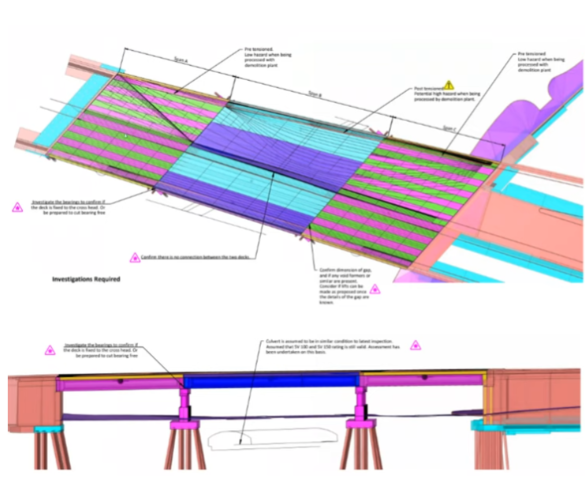

Demolition engineering for removal of a post-tensioned bridge with prestressed elements in central Leeds with a dual carriageway over the top of the structure in both directions and a main road underneath.

Additional complexity due to the small site footprint and the requirement to retain the original piers and abutments for use on the replacement structure.

There is also the large masonry sewer underneath. Clearly shown on drawings, and discussed in webinar

Client: Leeds Council

Contractor: Balfour Beatty

Demolition contractor: Sam Evans and Sons

SPMT and Lifting Contractor: Sarens