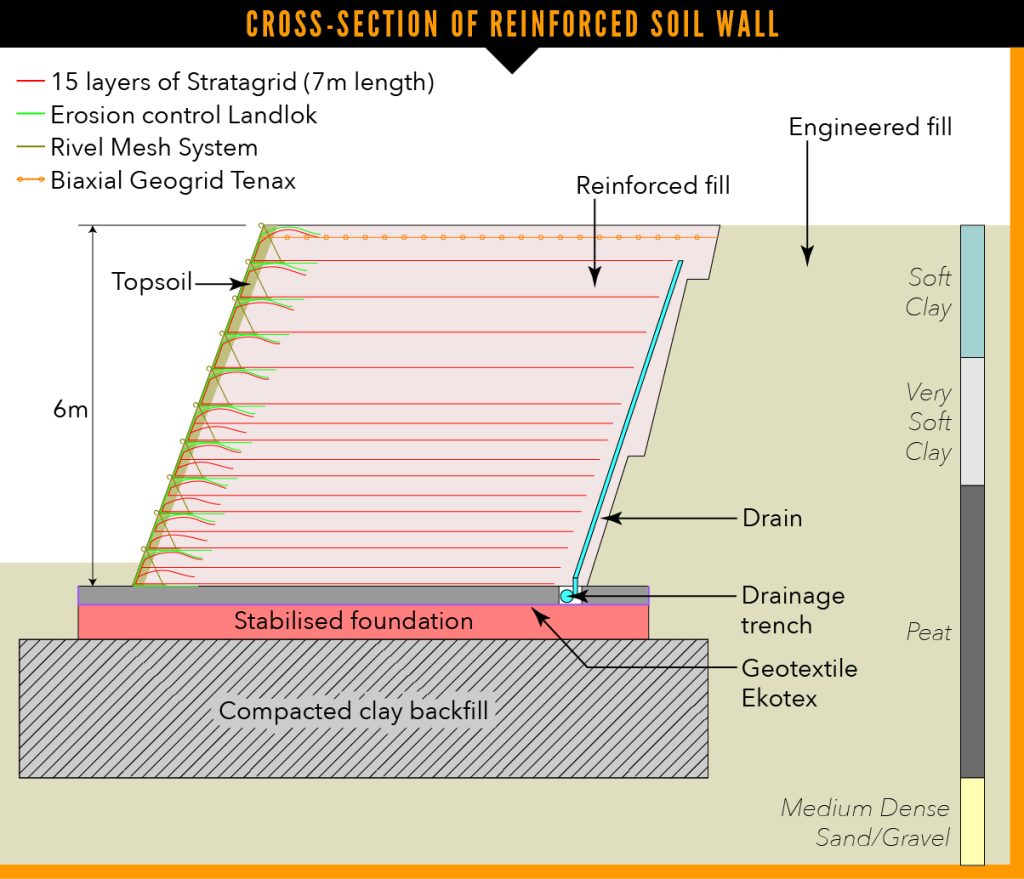

Design of an OPC retaining wall foundation on challenging ground, to support a brownfield housing development in London featured in Ground Engineering Magazine.

Client: Bellway London Partnerships

Principal Contractor: Statom Group

Supply chain: Andun Engineering Consultants, Geosynthetics & Geoman

Photo credit: Ground Engineering Magazine