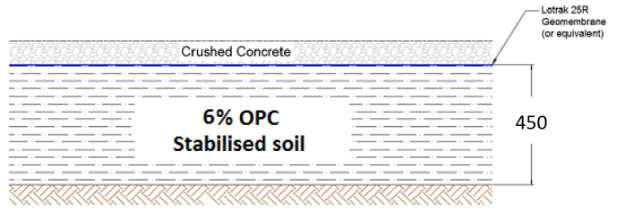

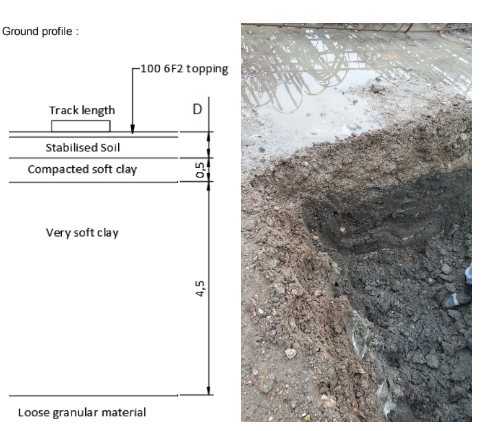

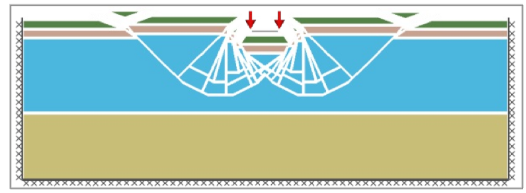

The design of an OPC stabilised piling mat to support various piling rigs at the Goodluck Hope project in East London.

The Goodluck Hope Project was a riverside regeneration project to create 841 homes, 2,300sq m of commercial space, 250sq m of education floorspace and a restored Grade II-listed Orchard Dry Dock.